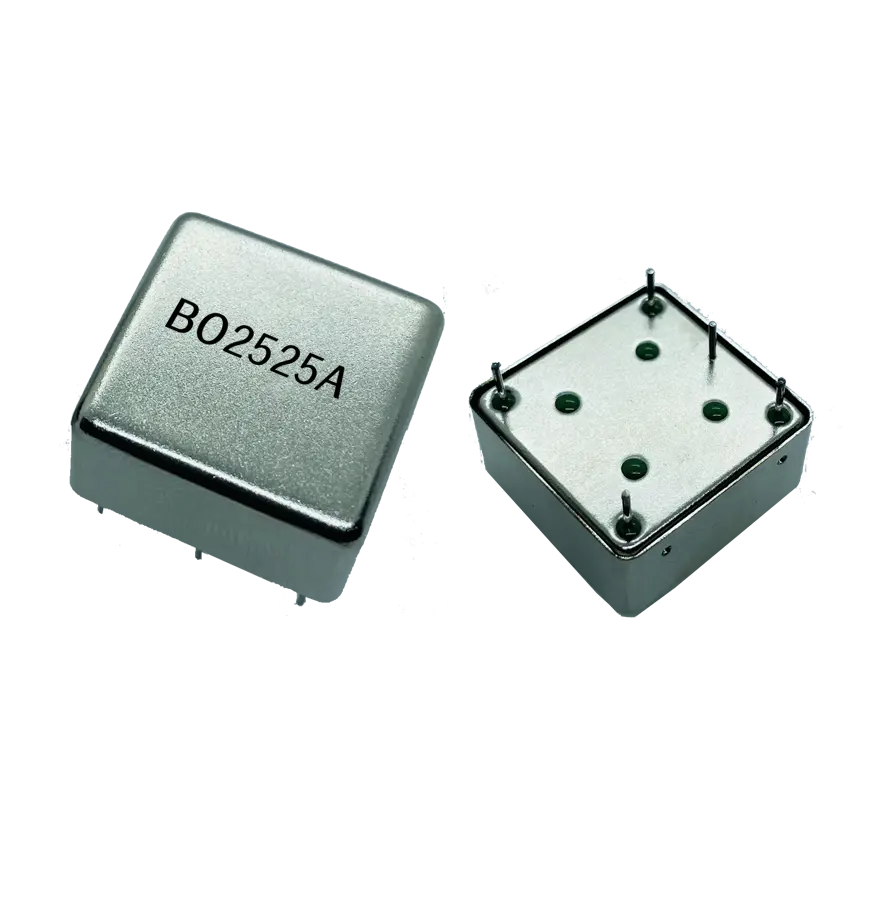

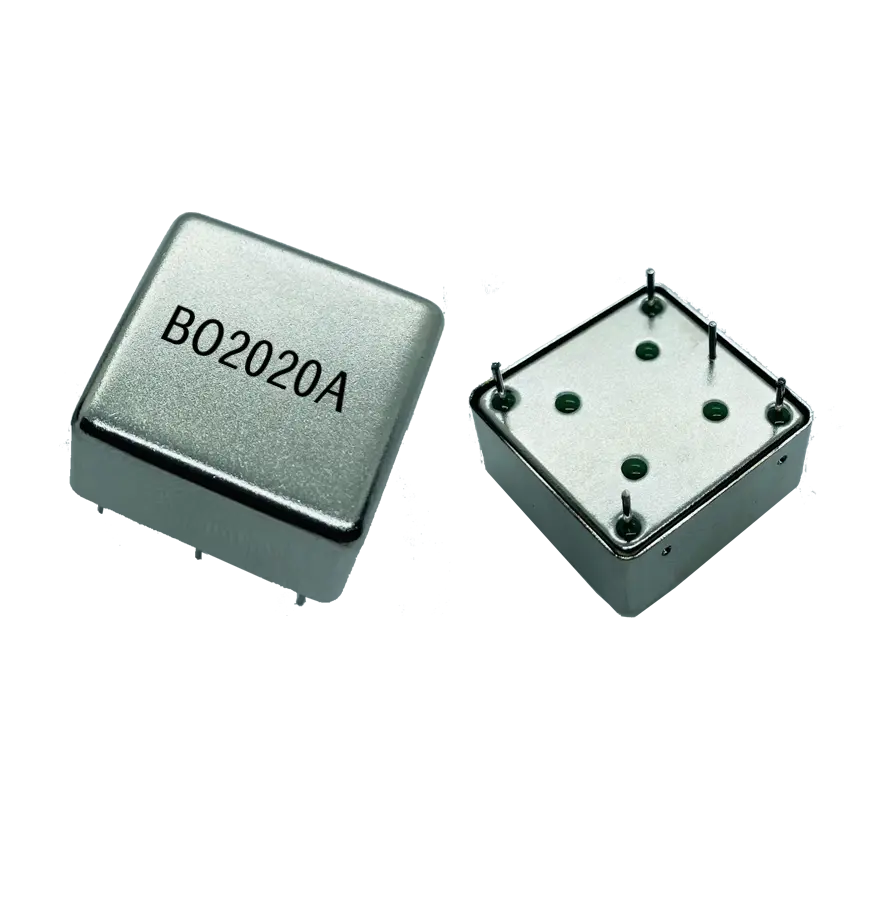

An Oven-Controlled Crystal Oscillator (OCXO) is a high-precision timing device that maintains a stable frequency by housing the crystal in a temperature-controlled oven. This design minimizes frequency variations due to temperature changes, making OCXOs ideal for applications requiring exceptional stability, such as telecommunications and scientific instrumentation. XtalTQ is a leader among OCXO manufacturers, specializing in high-precision, oven-controlled crystal oscillators. Our advanced technology ensures unparalleled frequency stability and reliability, making us the preferred choice for critical applications in telecommunications, aerospace, and defense. Trust XtalTQ for cutting-edge OCXO solutions tailored to your specific needs.

An Oven-Controlled Crystal Oscillator (OCXO) and a Temperature-Compensated Crystal Oscillator (TCXO) are both designed to provide stable frequency outputs, but they achieve this stability through different methods and have distinct characteristics.

An OCXO maintains its frequency stability by housing the crystal oscillator in a temperature-controlled oven. This oven keeps the crystal at a constant, optimal temperature, minimizing the effects of external temperature fluctuations. As a result, OCXOs offer superior frequency stability and precision, making them ideal for high-precision applications such as telecommunications, GPS systems, and scientific instrumentation. However, OCXOs are typically larger, consume more power, and have longer warm-up times compared to TCXOs.

In contrast, a TCXO uses electronic temperature compensation to adjust the frequency in response to temperature changes. This method involves adding temperature-sensitive components to the oscillator circuit to counteract the effects of temperature variations. While TCXOs are generally less stable than OCXOs, they are more compact, consume less power, and have faster warm-up times. TCXOs are suitable for applications where size, power efficiency, and moderate stability are important, such as in portable and battery-operated devices.

An Oven-Controlled Crystal Oscillator (OCXO) operates by maintaining the crystal oscillator at a constant, optimal temperature within a small, insulated oven. This design minimizes the impact of external temperature fluctuations on the crystal’s frequency stability.

Here’s how it works:

Crystal Oscillator: At the core of the OCXO is a quartz crystal that oscillates at a precise frequency. The crystal’s frequency can vary with temperature changes, which can affect the oscillator’s performance.

Temperature-Controlled Oven: The crystal is housed in a temperature-controlled oven. This oven is equipped with a heating element and a temperature sensor. The heating element keeps the oven at a constant temperature, typically higher than the maximum expected ambient temperature.

Control Circuit: A control circuit monitors the temperature inside the oven using the temperature sensor. It adjusts the heating element to maintain a stable temperature, ensuring the crystal operates in an optimal environment.

By keeping the crystal at a constant temperature, the OCXO significantly reduces frequency variations, providing exceptional stability and precision for applications requiring reliable timing and frequency control.

The advantages of using an OCXO include superior frequency stability, minimal impact from temperature variations, low phase noise, and high precision. These features make OCXOs ideal for applications requiring consistent and reliable performance in demanding environments.

What factors should be considered when selecting an OCXO? A: When selecting an OCXO, consider factors such as frequency stability, temperature range, phase noise, power consumption, and warm-up time. These parameters will determine the OCXO’s suitability for your specific application and its ability to maintain precise frequency control.

Yes, OCXO manufacturers offer customization options for OCXOs to meet specific performance, size, or environmental requirements. Custom orders may affect pricing and lead times.

English

English français

français Deutsch

Deutsch Español

Español русский

русский