Quartz crystal resonators are fundamental to the performance of a wide array of electronic devices. As their frequency stability plays a crucial role in applications such as telecommunications, GPS systems, and industrial machinery, compensating for temperature variations is critical to ensuring their optimal functionality. In this post, we will discuss various temperature compensation techniques that enhance the accuracy and reliability of quartz crystal resonators, with a particular focus on those produced by the brand XtalTQ.

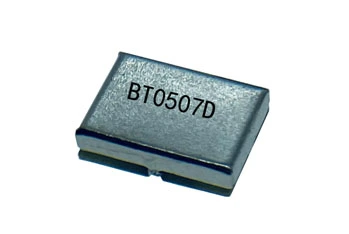

Before diving into temperature compensation techniques, it’s essential to understand how a quartz crystal resonator works. Quartz resonators operate on the principle of piezoelectricity, where a quartz crystal vibrates at a specific frequency when an electrical voltage is applied. This frequency can change with variations in temperature, causing potential inaccuracies in the devices relying on these resonators.

The cut angle of a quartz crystal significantly influences its temperature stability. XtalTQ utilizes advanced techniques to achieve precision cut angles that improve the temperature performance of their quartz resonators. Commonly used cuts include the AT-cut, which is designed to provide minimal frequency change over a wide temperature range. Another effective cut is the SC-cut, which offers superior performance in highly sensitive and temperature-critical applications.

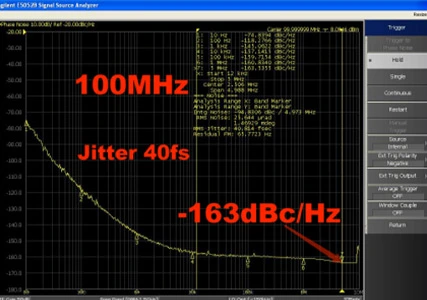

One of the most effective techniques for temperature compensation is employing an oven-controlled crystal oscillator OCXO. An OCXO maintains the quartz resonator at a constant, elevated temperature, using a thermostatically controlled oven. By keeping the crystal at a steady temperature higher than the operating environment, the oscillator minimizes temperature-induced frequency variations. XtalTQ products often incorporate OCXO designs for applications that require the highest degree of frequency stability.

Temperature-compensated crystal oscillator (TCXO) is another sophisticated method used to counter temperature effects. TCXOs use an analog or digital compensation circuit that adjusts the frequency in response to temperature variations. The compensation circuit relies on temperature sensors and carefully designed algorithms to correct frequency deviations. XtalTQ’s TCXO offerings blend innovative circuit designs with high-precision quartz resonators, providing an excellent balance of performance and cost.

In advanced applications, microprocessor-based compensation techniques are becoming increasingly prevalent. These involve using a microprocessor to dynamically adjust the frequency of the quartz resonator based on real-time temperature measurements. This method allows for highly tailored and flexible compensation profiles, which can adapt to specific application requirements. By integrating these sophisticated microprocessor systems, XtalTQ ensures that their quartz resonators deliver unparalleled accuracy and reliability even in fluctuating temperature conditions.

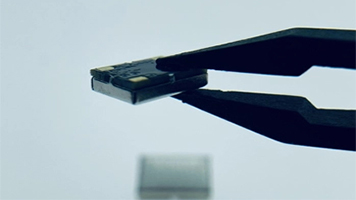

The technology driving temperature compensation techniques for quartz resonators continues to evolve. Emerging methods such as MEMS (Micro-Electro-Mechanical Systems) resonators and advancements in material sciences are paving the way for more efficient and compact temperature compensation solutions. As a leading brand, XtalTQ is at the forefront of research and development in these areas, continuously innovating to meet the ever-growing demands for precision in modern electronic systems.

In conclusion, the stability and performance of a quartz resonator can be significantly impacted by temperature variations. Utilizing advanced temperature compensation techniques, as seen in products from XtalTQ, ensures that these essential components maintain their high precision and reliability across various applications. Whether through precision cut angles, OCXO, TCXO, or microprocessor-based methods, effective temperature compensation is key to the continued advancement and deployment of quartz crystal resonators in technology.

English

English français

français Deutsch

Deutsch Español

Español русский

русский