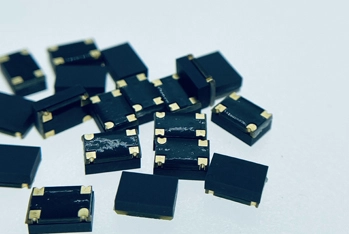

With different from ceramic package, Xtaltq's high-perfromance TCXO adopts plastic package because it has advantage in ultra stable, shock and vibration resistance, temperature compensated module and crystal hpysical thermal synchronization feature.

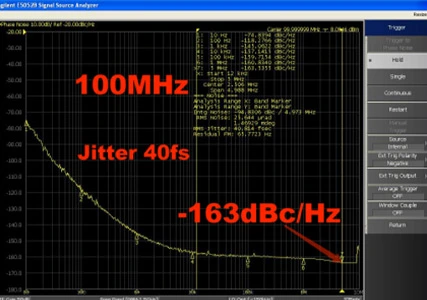

In the market, most of TCXO 7.0mm*5.0mm and 5.0mm*3.2mm are 2~0.5ppm for frequency stability. However,Xtaltq's TCXO can provide 0.1~0.05ppm, appoximately OCXO's stability. The competitive edge is compensation technology and self-researched IC. The temperature compensation IC sealed plastic can be integrated flexibility and higher reliability, which lays the foundation of developing reference clock used TCXO.

The process of plastic sealing IC is different from ceraic cavity package. The appearance of resonator is wrapped by plastic protective meterial for buffering, so it's better than others for shock and vibration resistance.

Given that temperature compensated devices, crystals and other circuits are wrapped by the same temperature coefficient package material and Xtaltq has uniqure thermal design structure, it is better for temperature compensated circuits and crystal thermal synchronization which can meet frequency compensated with the change of temperature.

English

English français

français Deutsch

Deutsch Español

Español русский

русский